I started a small manufacturing business a couple of years ago. While it almost took 15 months to reach the breakeven point, my small venture recorded an all-time high in profits last month. Now, you might be wondering how I became profitable in less than two years.

Well, according to the Small Business Administration, around 20% of small businesses shut down their operations in the first year. So, what did I do differently?

I reduced operational costs and focused on improving efficiency, productivity, and customer satisfaction. Thanks to Lean Six Sigma (LSS) certifications, which I fortunately had completed during graduation, it was all made possible.

That said, I’ll explain everything you need to know about Lean Six Sigma in this article. So, let’s start:

What is Lean Six Sigma?

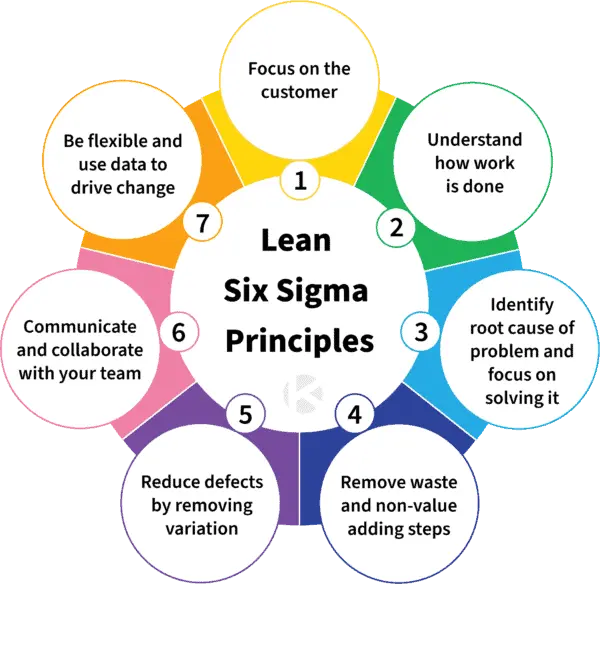

LSS is a combination of two processes, Lean and Six Sigma. These two methodologies combine into Lean Six Sigma and ensure that businesses stay efficient, maximize their profitability, and satisfy their customers.

The concept of Lean solely focuses on reducing a business’s waste, while the goal of Six Sigma is to reduce variations in different operations. The ultimate goal of lean and six sigma is to optimize business operations to achieve maximum efficiency.

However, Six Sigma specifically focuses on two approaches: DMAIC (Define, Measure, Analyze, Improve, Control) and DMADV (Define, Measure, Analyze, Design, Verify). Depending on what businesses want to achieve, they can use one of these Six Sigma strategies.

That said, a major difference between lean and six sigma is how they’re used. For instance, Lean takes help from less technical tools such as Kaizen. Whereas Six Sigma relies on statistical data analysis and process control, which might be complex and technical, but at the same time, quite effective in reducing iterations in business operations.

Now, dozens of online courses and certifications are available that teach Lean Six Sigma. You can thoroughly learn different concepts of Lean Six Sigma through such educational resources. That said, ensure your internet is up for the task, because such courses also test your knowledge with time-bound quizzes and assessments.

Personally, I’ve completed several Lean Six Sigma courses, and thanks to Verizon Internet, my home internet. Thanks to a reliable and high-speed connection, I’ve never failed any time-bound quiz or assessment. That said, I’ve briefly explained the major goals of Lean Six Sigma below:

- Eliminate Waste

Lean Six Sigma aims to eliminate waste in different business operations. By waste, it refers to tools, practices, or efforts that don’t add any value to business or customers.

- Reduce Variations

One of the primary factors in achieving high efficiency in business operations is reducing variations. Here, variations refer to inconsistencies and errors that can impact the quality of products or services.

- Increase Customer Satisfaction

Lean Six Sigma ensures customer loyalty and retention in the long term. The goal is to offer affordable and quality products/services that cater to customers’ needs.

- Increase Business Profits

The focus is to reduce waste, streamline business operations, and achieve the highest possible efficiency, which ultimately will increase business profits.

Types of Belts in Lean Six Sigma

Lean Six Sigma uses belts of different colors to represent the expertise of individuals in this methodology. It starts from the beginner level, which is represented by a White belt. And, goes up to expert level, which is denoted by a Master Black belt.

Below, I’ll explain the types of belts in Lean Six Sigma:

· White Belt

It is the introductory belt awarded to individuals possessing basic knowledge of Lean Six Sigma. The purpose of the white belt is to offer a surface-level understanding of major concepts and terms involved in Lean Six Sigma.

· Yellow Belt

This belt is awarded in the second stage, where individuals focus on understanding Lean Six Sigma in depth. Individuals get familiarized with the tools and techniques involved in the Lean Six Sigma process and become an active part of teams implementing such strategies.

· Green Belt

This is the third stage, designed for individuals who’ve understood and gained hands-on experience with Lean Six Sigma strategies. In this step, they learn to lead different Lean Six Sigma projects and provide training to others.

· Black Belt

At this step, the focus of an individual is to lead Lean Six Sigma projects full-time. Such people also train individuals pursuing white, yellow, and green belts. Other than this, black belt holders are actively engaged with Lean Six Sigma tools to optimize business operations.

· Master Black

This is the most advanced stage in Lean Six Sigma. A person having a Master Black Belt is capable of initiating Lean Six Sigma projects on their own, designing strategies, training individuals, and communicating with industry leaders to fill efficiency gaps.

Frequently Asked Questions

Are Lean Six Sigma courses and certifications paid?

Yes, most reputable courses and certifications in Lean Six Sigma are paid.

Are Lean and Six Sigma strategies always used together?

No, both strategies don’t always need to be used together.

Also Read-Why Dubai Residents Love These Smart Box Storage Solutions