Modern drainage systems demand precision-based cleaning methods that go beyond surface-level blockage removal. Selecting the best sewer jetter is no longer a matter of power alone; it requires an informed assessment of performance control, system compatibility, safety, and long-term reliability. Poor equipment selection can result in incomplete cleaning, pipe damage, or recurring maintenance issues. A professional approach focuses on identifying equipment that delivers consistent internal pipe restoration without compromising infrastructure integrity.

This guide outlines the most important technical and practical considerations that influence effective sewer jetting performance.

1. Pressure Regulation and Flow Precision

Effective sewer jetting begins with controlled pressure and consistent water flow, as these elements directly determine cleaning accuracy, pipe safety, and overall performance reliability.

- Adjustable Pressure Output: Precisely regulated pressure allows operators to adapt the cleaning force to pipe material, age, and blockage severity. Variable pressure control minimizes the risk of internal pipe damage while maintaining optimal cleaning power. This flexibility ensures effective removal of grease, scale, and hardened debris without overloading the system.

- Consistent Water Flow Delivery: Steady, uniform water flow ensures debris is fully flushed out rather than pushed further along the pipeline. Consistent output prevents residue buildup that can quickly lead to recurring blockages. This reliability improves overall cleaning efficiency and extends the time between maintenance cycles.

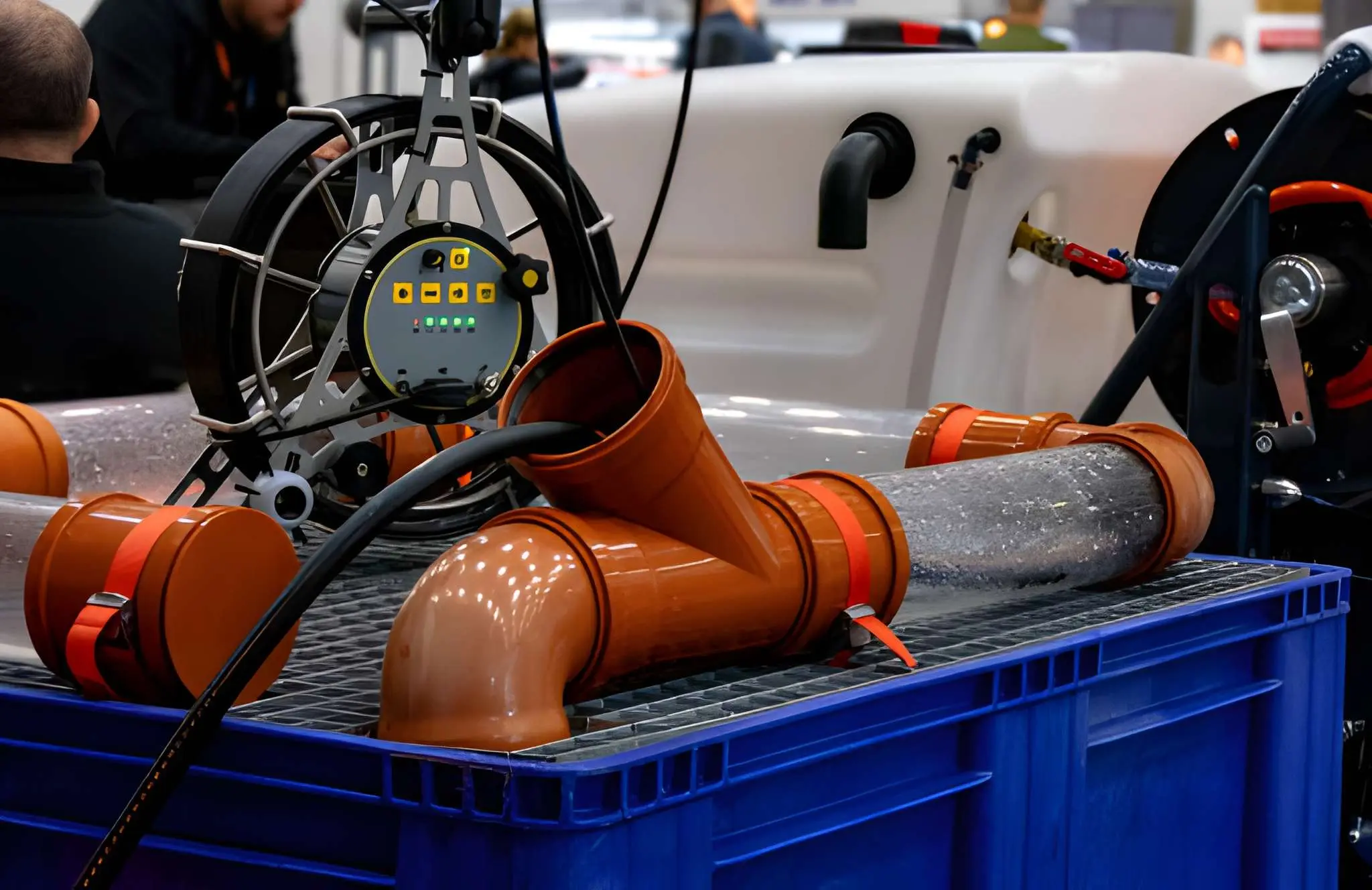

- Nozzle Performance Adaptability: Advanced jetting systems accommodate specialized nozzles for roots, grease, sand, and mineral deposits. Selecting the right nozzle enhances cleaning precision and targets obstructions more effectively. This adaptability reduces cleaning time, water usage, and operational downtime.

Choosing a jetter with precise pressure control and consistent flow ensures every cleaning operation is accurate, safe, and effective, maximizing debris removal while protecting pipe integrity.

2. Compatibility with Pipe Structure and Materials

Drainage systems vary widely in material composition and structural design, making equipment compatibility a critical factor in preventing damage while achieving thorough internal cleaning.

- Material-Sensitive Operation: Drainage systems often combine PVC, cast iron, and concrete pipes, each with different tolerance levels. Jetting equipment must adjust pressure and flow to suit each material without causing stress or cracking. This material-aware operation helps prevent premature wear and extends overall pipe lifespan.

- Pipe Diameter Flexibility: An effective jetter should clean small household lines as well as large commercial pipelines. Wide diameter compatibility eliminates the need for multiple machines or attachments. This flexibility improves operational efficiency and reduces maintenance time and costs.

- Internal Surface Protection: Efficient jetting removes grease, scale, and debris without eroding pipe interiors. Controlled pressure distribution prevents excessive abrasion during cleaning. This protection preserves structural integrity and supports long-term drainage performance.

Equipment that adapts to varied pipe materials and diameters preserves infrastructure longevity and delivers thorough cleaning without causing damage or requiring multiple tools.

3. Operational Efficiency and Workflow Optimization

Beyond cleaning capability, a sewer jetter’s operational efficiency plays a major role in reducing downtime, improving service delivery, and maintaining consistent maintenance schedules.

- Deployment Speed and Setup Efficiency: Quick-mobilization equipment minimizes preparation time and accelerates job start-up. Reduced setup complexity is critical for handling urgent blockages and planned maintenance alike. Faster deployment improves service response times and overall operational productivity.

- Hose Reach and Maneuverability: Long, flexible hoses provide access to deep, narrow, or complex drainage systems. Enhanced maneuverability allows smooth navigation through bends, joints, and intersections. This capability ensures comprehensive cleaning without frequent repositioning or interruptions.

- Sustained Performance Capability: Stable pressure output supports consistent cleaning over extended pipe lengths. Continuous performance prevents uneven results caused by pressure drops or surges. This reliability reduces the need for repeat servicing and improves long-term system efficiency.

Fast deployment, flexible hose reach, and reliable performance allow technicians to complete jobs efficiently, reducing downtime and improving overall maintenance productivity.

4. Safety Controls and Compliance Standards

Professional sewer jetting must prioritize safety and regulatory compliance to protect operators, infrastructure, and the surrounding environments during high-pressure cleaning operations.

- Integrated Pressure Safety Mechanisms: Safety valves and automatic pressure limiters prevent over-pressurization that could damage pipes or equipment. These mechanisms protect operators from sudden pressure spikes, ensuring safe working conditions. Reliable safety controls are essential for meeting professional standards and regulatory compliance.

- Operator Responsiveness and Control: User-friendly controls allow technicians to adjust pressure and flow in real time. Immediate responsiveness enables adaptation to varying pipe conditions and obstructions. Enhanced control improves cleaning efficiency while minimizing the risk of damage or accidents.

- Environmentally Responsible Operation: Water-based jetting removes blockages without relying on harmful chemicals. This approach reduces environmental impact and aligns with sustainable maintenance practices. Eco-friendly operation supports compliance with environmental regulations and promotes safer community infrastructure.

Integrating safety features, responsive controls, and environmentally responsible methods ensures operator protection, regulatory compliance, and sustainable cleaning practices.

5. Durability and Long-Term Maintenance Viability

Long-term performance depends on equipment durability and ease of maintenance, ensuring the jetter remains reliable under repeated use without escalating operational costs.

- Component Strength and Wear Resistance: Durable hoses and corrosion-resistant fittings ensure the system withstands repeated high-pressure operation. Robust construction minimizes the risk of leaks, bursts, or premature wear during intensive use. Strong components enhance reliability and reduce the frequency of costly replacements.

- Ease of Inspection and Servicing: Accessible design allows technicians to perform routine checks and preventive maintenance efficiently. Quick servicing reduces equipment downtime and keeps cleaning schedules on track. Simplified inspection procedures extend the lifespan of the jetting system and improve operational readiness.

- Performance Stability Over Time: Reliable systems maintain consistent pressure and flow throughout repeated operations. Stable performance ensures predictable cleaning outcomes and prevents uneven debris removal. Long-term consistency supports maintenance planning, reduces repeat interventions, and improves cost efficiency.

Robust components, easy servicing, and stable performance guarantee long-term reliability, reducing maintenance costs and supporting predictable, efficient pipe cleaning over time.

Final Thoughts

Selecting the right sewer jetter requires more than evaluating raw power; it demands a structured assessment of pressure control, material compatibility, operational efficiency, safety mechanisms, and durability. Equipment that balances these factors delivers reliable pipe cleaning while protecting infrastructure and reducing long-term maintenance risks. Informed selection supports consistent system performance, fewer emergency interventions, and greater operational confidence.

Those seeking pressure cleaning of drain pipes in Dubai can explore expert-led services at JB ALLO Sewage, where technical expertise is combined with advanced equipment and structured service processes. Their approach focuses on accurate system assessment, controlled cleaning methods, and long-term performance reliability. By prioritizing safety, efficiency, and infrastructure protection, JB ALLO Sewage supports consistent drainage functionality across residential, commercial, and industrial environments.

Also Read

- Making Eye Exams Smoother With Better Tech

- Marketing for Business Growth

- Procurement Systems with AI: From Automation to Intelligent Decision-Making