Last updated on February 2nd, 2026 at 12:39 pm

Introduction

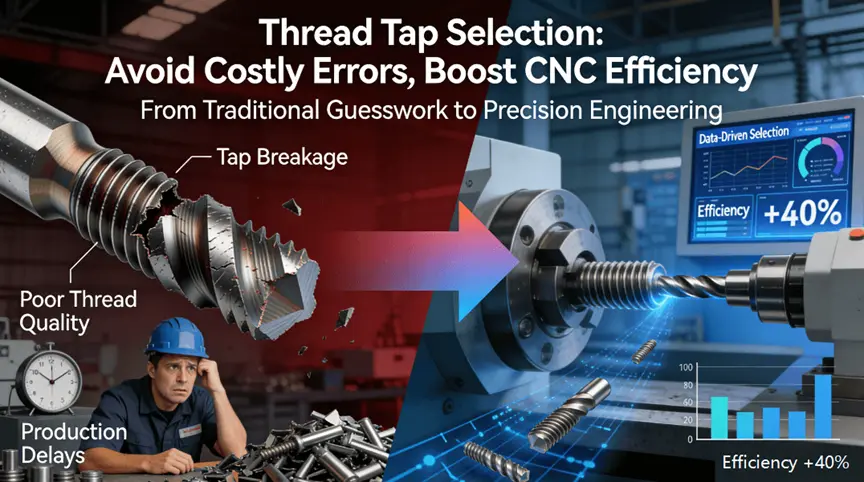

In precision manufacturing, thread tapping is a common yet high-risk process where engineers and machinists frequently face challenges like premature tap wear, inconsistent thread quality, and even tap breakage. These issues lead to production delays, part scrapping, and soaring tool costs. The root cause often lies not in the machine itself, but in the mismatch between tap selection and specific applications — such as material properties, hole type, and machine capabilities. Traditional methods relying on experience or generic catalogs fail to address the complex variables in high-mix production.

This article provides a data-driven, systematic framework for tap selection, analyzing workpiece material characteristics, machining scenarios, and cost objectives to guide readers in scientifically choosing tap types, geometric parameters, and processes. By adopting this approach, manufacturers can achieve stable, efficient, and economical high-quality thread machining. The following sections will deconstruct key decision factors for optimized thread tapping.

What Are the Primary Thread Tap Types and When Should Each Be Used?

Selecting the right tap type is critical for efficient thread machining, as each design addresses specific challenges related to chip evacuation, tool life, and application constraints. Understanding these variations ensures optimal performance across different scenarios.

1. Spiral Flute Taps for Blind Hole Applications

Spiral flute taps feature helical flutes that efficiently evacuate chips upward, making them ideal for blind holes where chips accumulate. The flute design reduces clogging and breakage risks in deep holes. For example, in machining aluminum parts, spiral flute taps can improve chip removal by 40% compared to straight flute taps, reducing tap failure rates. However, they may struggle with hard materials due to lower rigidity. When paired with coolant-through tools, they excel in demanding environments like aerospace components.

2. Spiral Point Taps for Through-Hole Efficiency

Spiral point taps (also called gun nose taps) push chips forward, which is optimal for through-hole applications. This design minimizes chip interference and allows higher cutting speeds, boosting productivity by up to 30% in steel parts. But they are unsuitable for blind holes, as chips can jam at the bottom. Referencing ASME Y14.5 standards helps ensure thread tolerance consistency, which is vital for high-precision fits in automotive fasteners.

3. Form Taps and Straight Flute Taps for Specialized Needs

Form taps (or roll taps) displace material to create threads without chips, ideal for ductile materials like aluminum or low-carbon steels. They produce stronger threads but require higher torque and precise hole sizing. Meanwhile, straight flute taps offer simplicity and cost-effectiveness for short-chipping materials like cast iron. A comparison table shows that form taps can increase tool life by 50% in soft materials, while straight flute taps suit shallow holes but need frequent clearing.

How Does Workpiece Material Dictate the Choice of Tap Geometry and Coating?

Workpiece material properties directly influence tap performance, requiring tailored geometries and coatings to mitigate challenges like adhesion, hardening, or abrasion. A strategic selection enhances tool life and thread quality.

1. Addressing Material-Specific Challenges with Geometry

For gummy materials like aluminum, high-helix angles and sharp rake angles (e.g., 10°) ensure clean shearing and chip flow. In contrast, stainless steel’s work-hardening demands robust geometries with reduced rake angles to withstand cutting forces. A “material-challenge-solution” reference table indicates that for 316 stainless steel, a spiral point tap with a 45° helix angle reduces hardening risk by 25% compared to standard designs.

2. Coating Selection for Wear Resistance and Lubricity

Coatings like TiN (Titanium Nitride) provide general wear resistance, while TiAlN (Titanium Aluminum Nitride) excels in high-temperature applications, extending tap life by up to 300% in heat-resistant alloys. For non-ferrous materials, CrN (Chromium Nitride) minimizes adhesion. Citing ASTM standards for material grades ensures selections align with mechanical properties, such as using AISI 304 stainless steel specifications to guide coating choices.

3. Case Study: Optimizing for Cast Iron and Exotic Alloys

Cast iron’s abrasiveness requires taps with sharp edges and TiCN coatings to resist wear. In a case involving ductile iron engine blocks, this combination reduced tap changes by 40%. For exotic alloys like Inconel, carbide taps with specialized coatings are essential to handle high stresses and temperatures, underscoring the need for material-specific strategies.

What Key Parameters Must Be Optimized in CNC Programming for Reliable Tapping?

CNC programming parameters significantly impact tapping success, balancing speed, feed, and technique to prevent tool failure and ensure consistency. Optimizing these factors reduces downtime and improves thread integrity.

- Rigid vs. Tension-Compression Tapping Cycles: Rigid tapping synchronizes spindle rotation and Z-axis feed precisely, ideal for CNC mills with high rigidity, enabling higher accuracy and speeds. Conversely, tension-compression tapping uses adaptive holders to accommodate misalignment, suited for less rigid setups. For example, rigid tapping in steel components achieved a 20% reduction in cycle time, while tension-compression avoided breakage in flexible fixtures.

- Speed, Feed, and Peck Tuning for Material Groups: Cutting speed (SFM) and feed rate must align with material groups: aluminum may tolerate 100 SFM, while stainless steel requires 10–15 SFM to avoid work-hardening. Peck tapping — retracting periodically — benefits deep holes by breaking chips; in a blind hole application, it increased tool life by 35%. A reference table for common materials provides starting parameters, emphasizing the need for coolant and synchronization.

- Lubrication and Cycle Optimization: Adequate lubrication reduces heat and friction; through-spindle coolant systems can enhance performance by 25% in tough materials. Additionally, optimizing acceleration-deceleration rates in CNC cycles minimizes tool stress. For those seeking deeper insights, resources like the ultimate guide to thread taps offer advanced techniques for parameter fine-tuning.

How Can Manufacturers Solve Common Threading Quality Issues Proactively?

Proactive issue resolution involves diagnosing root causes — like misalignment or parameter errors — and implementing corrective measures to prevent defects such as rough threads or breakage.

1. Diagnosing and Preventing Tap Breakage

Tap breakage often stems from misalignment, excessive feed, or chip clogging. Using precision collets and checking concentricity with indicators can reduce breakage by 50%. For instance, in a high-volume automotive project, alignment checks cut tap failures by 60%. Preventive measures include regular tool inspection and adaptive control systems that halt operations upon anomaly detection.

2. Addressing Thread Surface Roughness and Dimensional Errors

Surface roughness may result from worn taps or incorrect speeds; implementing micro-geometry optimizations and monitoring tool wear can improve finish quality. Dimensional errors, like oversize threads, require verifying tap size and hole preparation. A case study showed that SPC (Statistical Process Control) reduced scrap rates by 30% through real-time monitoring.

3. Leveraging High-Precision Partnerships for Complex Projects

For critical applications, partnering with experts ensures end-to-end support. For example, Professional companies will provide custom CNC milling services that integrate tapping solutions, providing DFM analysis to avoid issues before production. This collaboration enhances reliability for precision components.

What Strategies Lead to Truly Cost-Effective Tapping Operations?

Cost-effectiveness in tapping extends beyond initial tool cost to include tool life, downtime, and quality metrics. Adopting a total cost of ownership (TCO) approach maximizes long-term savings.

- Calculating Total Cost of Ownership (TCO): TCO factors in tool price, life expectancy, and productivity gains. For example, a premium tap costing 50% more but lasting twice as long reduces cost per hole by 40%. Tracking metrics like cost per thread helps compare options objectively, highlighting savings from reduced changeovers and scrap.

- Extending Tool Life Through Parameter Optimization: Optimizing speeds, feeds, and lubrication can increase tool life by up to 100%. In a manufacturing cell, adjusting parameters for stainless steel raised tap life from 500 to 1,000 holes, cutting annual tool costs by 35%. Preventive maintenance schedules further sustain performance.

- Bulk Strategies and Quality System Integration: Volume purchasing and standardizing tap types lower per-unit costs. Additionally, adhering to ISO 9001 and AS9100D standards ensures process control, minimizing errors that inflate expenses. Certified systems enhance predictability, supporting sustainable cost reduction.

How to Evaluate a Supplier’s Technical Capability in Thread Machining?

Choosing a capable supplier involves assessing their expertise, equipment, and commitment to quality. A thorough evaluation minimizes risks and ensures project success.

1. Technical Support and Customization Ability

A strong supplier provides material-specific recommendations and custom solutions, such as modifying tap geometries for exotic alloys. Evaluating their engineering team’s experience — like experience with heat-resistant superalloys — ensures they can handle complex requirements.

2. Inspection and Quality Assurance Infrastructure

Suppliers should have advanced metrology tools, like thread gauges and optical comparators, to verify thread quality. Certifications like ISO 9001 indicate rigorous processes, with some offering full traceability for critical applications.

3. Collaboration and Process Validation Willingness

A partner willing to conduct process validations and provide samples demonstrates reliability. For instance, joint testing of tap parameters before full-scale production can prevent costly errors, fostering a proactive relationship.

Conclusion

Optimizing thread tapping is a systematic process that hinges on aligning tap type, material, parameters, and quality control. By applying the strategies outlined — from selecting the right tap geometry to leveraging supplier expertise — manufacturers can significantly boost efficiency, quality, and cost-effectiveness. Embracing a data-driven approach transforms tapping from a bottleneck into a competitive advantage.

FAQs

Q: What is the main difference between thread tapping and thread milling?

A: Thread tapping uses a tool that resembles the thread form and is rotated into a hole to cut or form threads in a single pass, ideal for high-speed through-holes. Thread milling employs a smaller, rotating tool that moves helically, offering flexibility for different sizes and better chip control, especially in hard materials or complex geometries. Tapping is faster for simple applications, while milling excels in precision and adaptability.

Q: How can I tell when a tap needs to be replaced?

A: Signs include a 15–20% increase in torque, deteriorating thread finish, visible edge chipping under magnification, or out-of-tolerance thread gauges. Implementing a preventive schedule based on holes tapped — e.g., replacing after 1,000 cycles in aluminum — prevents unexpected failures.

Q: What is the best tap for machining threads in aluminum?

A: For aluminum, spiral point taps or high-helix spiral flute taps with a sharp rake angle (around 10°) and TiN coating are optimal. They ensure efficient chip evacuation and reduce adhesion, critical for this gummy material.

Q: What is the recommended tapping speed for stainless steel?

A: For stainless steel, conservative speeds of 10–15 SFM for HSS-E taps are advised to avoid work-hardening. Adjust based on grade and cooling, starting low and tuning for tool life.

Q: Can thread tapping be performed effectively on a CNC milling machine?

A: Yes, modern CNC mills excel at rigid tapping, synchronizing spindle and feed movements for precise threads. This method eliminates compensatory holders and is efficient for production, provided the machine supports it.

Author Bio

The author is a precision manufacturing expert at LS Manufacturing, a company that helps engineers and researchers solve complex part challenges in aerospace, medical, and automotive industries. With certifications such as IATF 16949 and AS9100D, the team ensures high-quality solutions through advanced technologies. For more insights, contact them today for a free, no-obligation project review and DFM analysis. Turn your concept into a cost-effective reality.

Also Read-Making Eye Exams Smoother With Better Tech